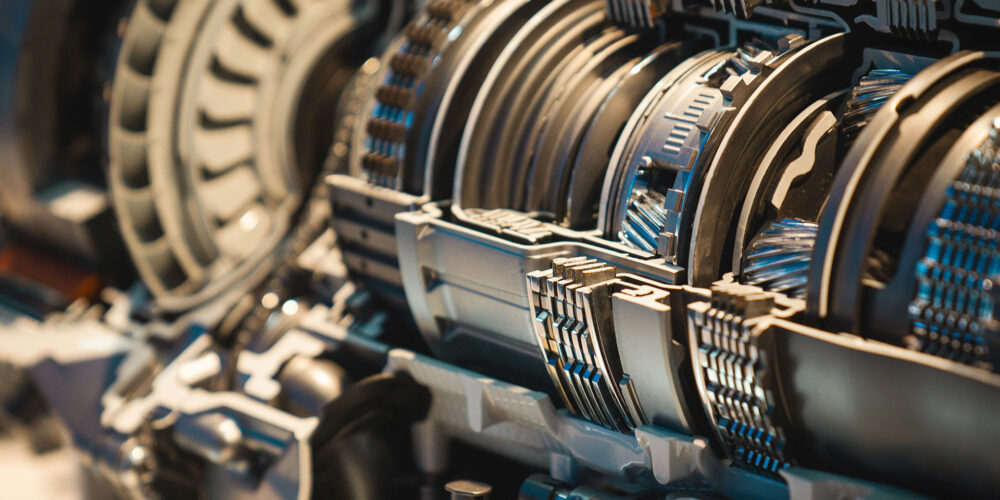

For over a century, the gearbox has been the beating heart of how we interact with our cars. Whether manual or automatic, CVT or dual-clutch, transmission systems have shaped how vehicles accelerate, cruise, and climb hills. But now, with the rise of electric vehicles (EVs), that cornerstone is starting to disappear.

At Service4Service, we’ve spent years repairing and maintaining all types of transmissions, from complex dual-clutch units to rugged off-road gearboxes. But as EVs roll into the mainstream, we’re seeing a major shift. Many of these new vehicles simply don’t need traditional gearboxes at all.

So, what happens next? Let’s take a closer look at why electric cars are ditching the gearbox, and what might replace it.

Why Electric Vehicles Don’t Need Multi-Speed Transmissions

Traditional internal combustion engines (ICE) rely on transmissions to stay in their “power band.” They produce usable torque within a limited RPM range, so the gearbox steps in to keep the engine spinning where it performs best.

Electric motors, on the other hand, deliver maximum torque from zero RPM. They’re not bound by narrow power curves, and they can spin far higher, often over 15,000 RPM, without needing gear changes.

In most EVs today, a single-speed reduction gear is all that’s needed to convert the motor’s high-speed output into usable wheel torque. That means no gear hunting, no shift delays, and no clutches to worry about. It’s smooth, silent, and direct.

The End of the Gearbox as We Know It?

We’re not saying transmissions are gone entirely. EVs still use a reduction gear, which is technically a type of single-gear transmission. But in terms of what most drivers think of as a gearbox, with multiple speeds and moving shift mechanisms, those are quickly becoming obsolete in the electric age.

What does this mean for the industry?

- Fewer mechanical components to fail

Without clutches, gearsets, and torque converters, there’s less to wear out. EVs generally require less drivetrain servicing than petrol or diesel vehicles. - New servicing priorities

The focus shifts from fluid changes and gear replacements to software diagnostics, cooling system maintenance, and battery conditioning. - Simpler drivetrains

With fewer moving parts, EVs are often cheaper to assemble (though not yet cheaper to buy). And they’re lighter and more efficient as a result.

What Might Replace the Traditional Gearbox?

Even though most EVs use single-speed setups, not every manufacturer is ready to let go of gear changes. Here’s what we’re seeing as potential “replacements” for the traditional gearbox:

1. Two-Speed Transmissions (For Performance EVs)

Some high-performance EVs, like the Porsche Taycan, use a two-speed gearbox on the rear axle. The first gear delivers brutal acceleration from a standstill, while the second supports higher-speed efficiency and top-end performance.

Why add the complexity back in? Because not every EV use case is the same. When speed, range, and efficiency need to be balanced, especially in sports cars or towing vehicles, gearing can help.

2. Software-Based Torque Control

One of the biggest shifts we’re seeing is away from mechanical solutions and toward software-defined driving. In an EV, acceleration isn’t dictated by engine RPM and gear ratios, it’s handled through software that precisely controls the flow of electricity to the motor.

Instead of shifting gears, the vehicle simply adjusts motor speed and torque delivery in real-time. It’s seamless, efficient, and often customisable. Drivers can select modes (Sport, Eco, Comfort) that affect performance, all without a single mechanical shift.

3. Multi-Motor Systems with Virtual Gearing

More advanced EVS are turning to multiple electric motors, one for each axle or even each wheel. This opens the door for “virtual” gear strategies, where software mimics the effects of gear changes by adjusting torque delivery from different motors.

What This Means for Drivers

Smoother Driving, Less Maintenance

The biggest benefit for everyday drivers is the simplicity. With no gear changes, EVs feel smoother, especially in stop-start traffic. There’s less mechanical wear and tear, fewer fluid changes, and no clutch-related problems.

At Service4Service, we’ve already seen how this reduces long-term drivetrain issues. That said, EVs aren’t maintenance-free. Cooling systems, inverters, drive motors, and software need expert attention. And because EV tech is evolving fast, so is our approach to servicing it.

Changing Expectations Behind the Wheel

Many drivers transitioning from ICE vehicles notice the difference immediately. There’s no downshifting before an overtake, no rev-matching, no shift lag. Just pure, linear acceleration.

For driving enthusiasts, this raises questions: Is this still “fun”? For some, yes, it’s the immediacy of EV power that thrills. For others, the lack of driver involvement in shifting takes something away. That’s a debate still unfolding.

The Road Ahead

The death of the traditional gearbox might feel like the end of an era, but it’s also the beginning of something new. As EV technology matures, we’ll see more clever alternatives to gearboxes emerge. Multi-motor control systems, dynamic torque mapping, and smart energy management will define the future of vehicle performance and drivability.

At Service4Service, we’re embracing that future. We’ve expanded our capabilities to include hybrid transmission repair, EV diagnostics, drive system servicing, and high-voltage training, so we’re ready for whatever comes next. Because, whether it’s gears, software, or something in between, one thing won’t change – drivers still want vehicles that perform and systems they can trust. Want to know more about EV drivetrain servicing or book an electric vehicle inspection? Get in touch with our expert team at Service4Service today.